Process analytics (Conductivity and pH-measurements) – SI Analytics

Measuring equipment:

Conductivity and pH-measurements are two important parameters in process analytics as well as in analytics for batch release.

CANDOR chose a two-step system. Process analytics is done with very robust and easy-to-operate devices. Lab 970 devices for conductivity measurements during production are used, while Lab 870 devices for pH-measurements are utilized. Both kinds of devices are used with direct connection to a printer to record measurement results. Each production station has its own set of these instruments. Every measurement result during production is printed automatically. The print-outs include electrode-identification, user-identification and batch numbers of the current batch. Additionally the read-outs are documented manually for any production protocol by the users. Robustness, ease of use and straightforward cleaning characteristics due to enclosed and smooth surfaces were important factors for choosing these devices. The devices are used in a production room and thus they have to withstand demanding use in such an environment.

Measurements for batch release are done on another device, which is independent from the process analytic devices. This is a ProLab 4000 pH/ION/Conductivity meter. It is used only for batch release testing for quality control. For any measurement the user has to identify himself at the device by a personal ID Card through transponder and optionally in addition by a personal password. The device provides wireless sensor recognition for automated electrode and measuring instrument identification and data exchange. Any relevant data, including batch data, user names, time of measurements, current calibration data, identity numbers of the used ID, SCHOTT® Instruments electrodes and of course the conductivity and pH-values are saved in the device memory as well as printed automatically for the batch documentation. As the device has two different user levels, one for lab technicians and another one for the system administrator, data integrity of any measurement results can be guaranteed. Thus this ProLab 4000 device can even be used for GLP laboratories (Good Laboratory Practice). The data integrity, documentation and traceability are especially important aspects for quality control instruments in the CANDOR facility. The user identification is printed out for any production protocol. Thus the quality control manager can check for any batch easily, who produced the batch and who did the batch release measurements. Thus it can be ensured easily that a user cannot release a self produced batch. This enables a double control of any batch.

After obligatory control of the complete production documentation each batch is released for sale personally by the leading quality control manager. As the quality control manager never works in production, a strict control for any new batch can be ensured.

Electrodes:

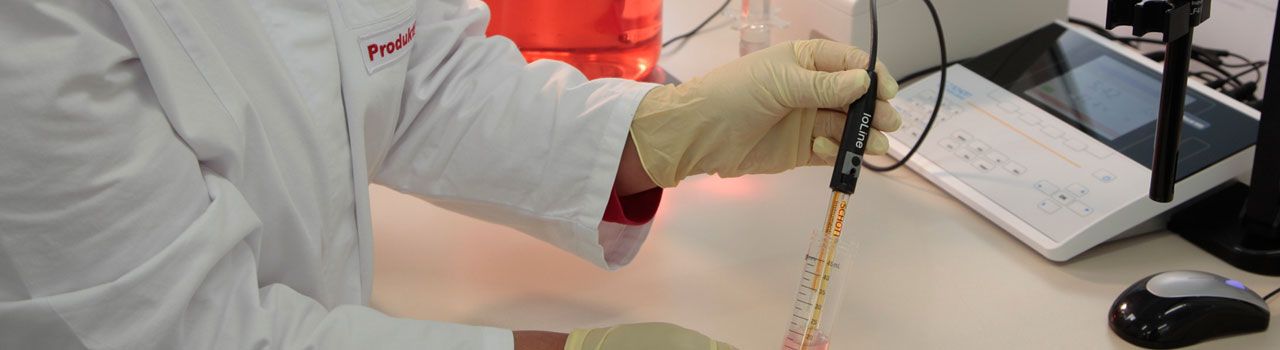

Strict analytic specifications need very robust and reproducible measurements in any situation. Thus good electrodes are a precondition for ensuring optimum measurement performance and product safety. The modern Iodine/iodide reference system electrode produced by SI Analytics is very robust, accurate and non-sensitive for any malfunction. We tested this new electrode-type called IoLine extensively and found it to be advantageous in our applications. This electrode system is very robust even when using TRIS as a buffer substance, which is critical with silver/silver-chloride electrodes as it can build up insoluble aggregates with silver ions. Such aggregates can lead to inaccuracy in measurements and even to complete loss of the electrodes. For ensuring product quality of CANDOR solutions, it is essential to always work with perfect electrodes. Another advantage of this new electrode type is the double diaphragm system. One has to refill only the electrolyte bridge instead of electrolyte solutions, electrolyte bridge and reference electrolyte. One may choose the electrolyte bridge according to the specific needs of the matrix for measurements.

Another aspect, which is interesting for measuring some of the CANDOR solutions is the ability to measure proteinaceous solutions without any problems. Therefore, even high protein concentrations cannot result in problems like silver-protein aggregates.

Such aggregates are well-known for silver-staining procedures in protein analytics, but they are completely unwanted on the surface of electrode diaphragms. Since with the Schott® Instruments Ioline electrode no such aggregates can arise, the electrodes can be used in a very wide spectrum of different solutions. Furthermore such electrodes show a very fast response-time, which is essential for production processes like titrations, where fast response is needed to ensure highest quality even with fast processing times.

The team of SI Analytics assisted our scientists and technicians not only during the process of choosing the right devices and electrodes. The team also assisted during implementation of the devices including the extensive IQ-/OQ (Instrument Qualification / Operation Qualification) process, which is documented according to standard protocols of SI Analytics with specific adaptations to the CANDOR Bioscience quality management system.

Thus using the SI Analytics devices was enabled during a very short implementation period without any interruption in batch productions.

More information